EPR

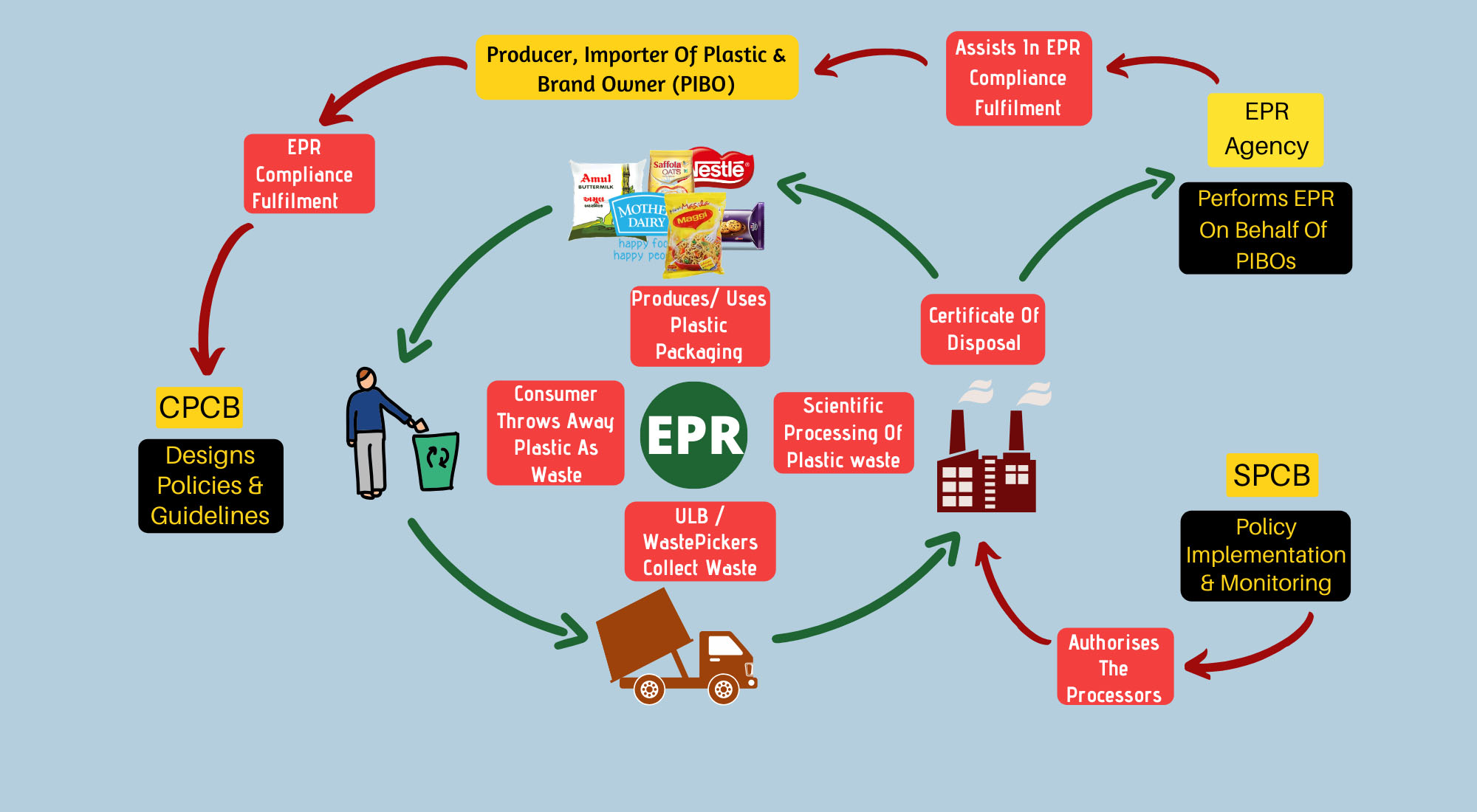

Extended producer responsibility, refers to the responsibility for the management of the disposal of products by producers once those products are designated as no longer useful by consumers. Our main objective is to develop an effective and efficient system that takes care of the collection, segregation, and transportation of the material to the waste disposal facility which is approved by the MPCB and CPCB as a PRO Agency. These materials are also used in cement kilns, pyrolysis, for road construction and recycling centers, on the basis of their quality and price.

REGISTRATION/IMPLEMENTATION

- Process starts with registration at CPCB/SPCB by submission of relevant documents required by CPCB which mainly consist of an action plan, agreement, certificates, licenses, etc.

- Next step starts with the role of authorised waste management agency to collect back agreed volume of post consumer plastic waste in a period of 1 year from desired location and recycle or dispose it safely as per CPCB/SPCB guidelines.

- Waste collection agency will present relevant documents for proof of waste collection activity

- On behalf of PIBOM’s agency will submit quarterly report to CPCB.

- After completion of activity final report will be submitted by agency to PIBOM’s